Construction of cutting-edge facility promotes chemical recycling of plastics

We are collaborating with various technology and other partners to construct a cutting-edge facility for chemical recycling of plastics in the Kilpilahti area of Porvoo, Finland. This project is exceptional because it marks the first time such a large-scale facility for chemical recycling of plastics will be established in Finland.

Challenge

This innovative project is groundbreaking in respect to scaling up chemical recycling and plastics. The recycling plant will efficiently make use of waste plastics not suitable for mechanical recycling. Hence the raw materials will be chemically recycled for utilisation as raw material in the petrochemical industry. The produced raw material can then be transported to suitable refineries for further processing.

Solution

We publicly announced the construction of this chemical recycling facility in Kilpilahti on June 22nd, 2022. During this year, we will focus on finalising the process design with the selected technology suppliers and constructing the processing plant to be able ramp up production in 2024.

During the initial phase, our aim will be to process recycled plastics at an annual capacity of 10,000 tons in our proof-of-concept production facility. Then we will increase this plastics recycling capacity to reach approximately 40,000 tons annually. This second phase is estimated to be completed by 2026.

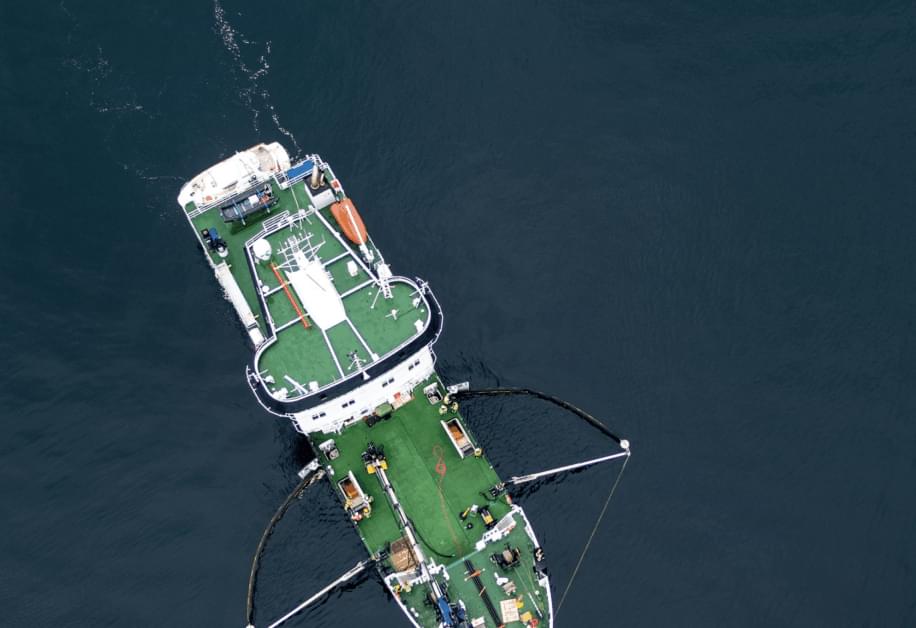

Lamor's approach to strategy implementation is founded on the principle of acting globally while remaining rooted in local contexts. By leveraging our global distribution network and project delivery expertise, we provide solutions that meet global quality standards while accommodating the specific needs and demands of our customers' operating environments. Building upon these competitive advantages, Lamor is now expanding its offerings to include plastics recycling solutions.

“This investment is the first significant step for Lamor to develop recycling of plastics. Our goal is to initially build this proof-of-concept plant in Finland, after which we will scale-up our production platform internationally within targeted market areas. This project is one example of our commitment on the green transition while participating in solving the global plastics problem with a 100-kiloton project portfolio of recycled plastics,” says Johan Grön, Chief Operating Officer of Lamor.

Impact

Currently, around the world, there are considerable efforts to replace part of the virgin crude oil in the petrochemical industry as a way of combating climate change.

By making advanced chemical recycling techniques available, we’re able to significantly increase the amount of recycled plastics and sustainable raw materials that are incorporated in raw material streams for the petrochemical industry.

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.