How harshest Arctic conditions overcome with oil spill response capabilities

Lamor's Arctic oil spill recovery solutions endure even the harshest of conditions. Imagine a frigid February night in the Arctic - an oil spill would be catastrophic. In 2011, a 165-meter container ship ran aground, between Norway and Sweden, in these unforgiving conditions. Thankfully, Lamor was ready with their cutting-edge technology to mitigate the disaster.

Challenge

Despite quick action to contain the leaking vessel with booms, a significant amount of heavy fuel oil had already escaped, posing a threat to Sweden’s Kosterhavet national park and Norway’s Ytre Hvaler park. The situation was further complicated by constantly shifting winds and currents that caused the oil to spread in unexpected directions, while sea ice added an extra challenge to the collection efforts.

Solution

Swedish and Norwegian authorities responded to the spill due to its location. On the first day, the Swedish Coast Guard dispatched two oil recovery vessels equipped with Lamor's in-built systems, operated by experienced crews. The following day, a new vessel, the KBV 001, also equipped with Lamor's in-built oil recovery system, was added to the operation by the Swedish Coast Guard.

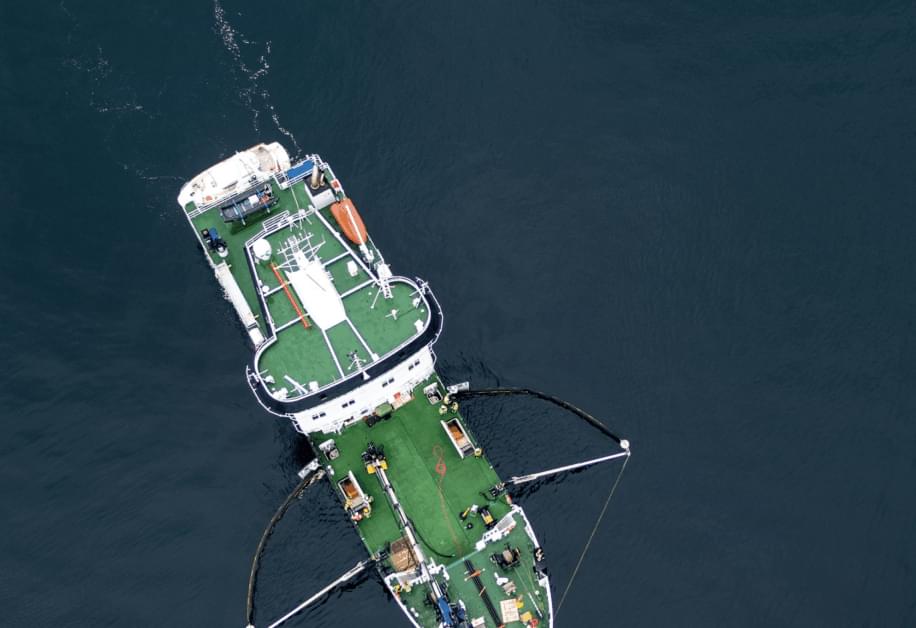

The Lamor in-built oil recovery system LORS is a vessel-mounted advancing skimming system. As the vessel advances in an oil slick, booms on the sides trap oil which is efficiently collected with conveyor chain brushes. Consequently, with LORS, the entire vessel is transformed into an incredibly effective oil slick processing system.

As the clean-up operation progressed temperatures dropped, and ice began to form. However, Lamor's heated brush cleaner, oil collection sump and cargo tanks enabled the recovery to continue.

The two Norwegian Coast Guard vessels then towed a U-shaped boom to concentrate the oil towards the KBV 001 vessel at the bottom of the U sweep. This enabled it to retrieve the collected oil.

“In cold weather conditions the first thing you need is equipment capable of handling ice. If you can’t work in ice, you can’t collect the spilled oil. Lamor’s OSR solutions were created to handle the coagulated oil, ice and freezing temperatures of Arctic weather,” says Rune Högström, Head of Spill Response.

Impact

In demanding conditions, Lamor's customer, the Swedish Coast Guard, was able to recover the oil quickly, safely, and efficiently. This prevented an ecological, economic, and reputational disaster that could have affected the fragile marine ecosystem of two national parks.

In seven days, the clean-up operation was complete. In total, 110 cubic metres of spilled heavy fuel oil were collected, over half from the open sea. The ice and sub-zero temperatures were dealt with by Lamor’s robust equipment and heated elements, while the brush conveyor belts safely collected the thickened and heavy oil. The free water content of the collected oil was less than 5 per cent. The crews were happy that their decks remained clean during the whole operation, giving them a safe and pleasant work environment.

Within a week, the clean-up operation successfully collected 110 cubic metres of heavy fuel oil. More than half of this was collected from the open sea. Despite the challenges posed by sub-zero temperatures and ice, Lamor's equipment and heated elements were incredibly successful in dealing with the situation. What’s more, the brush conveyor belts safely collected the thick and heavy oil while ensuring that the free water content of the collected oil was less than 5%. The crews were also happy as as Lamor's equipment kept the decks clean throughout the process, providing a safer and more pleasant working environment.

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.