Lamor cleaning up a difficult bitumen mix spill in China

When a million barrels of bitumen mix spilled into the sea off the coast of China, it seemed like an impossible task to clean it up. The sticky, nearly solid mass was difficult to contain and recover, and even tracking it was a challenge. Lamor’s inbuilt oil recovery systems proved their effectiveness in dealing with even the most difficult spills preserving the environment and wildlife.

Challenge

In heavy fog, a bulk vessel collided with a tanker off the coast of China, causing a breach in the tanker’s cargo tanks. Onboard was about one million barrels of bitumen mix. A preliminary estimate was that about 2,800 barrels were spilled into the sea.

Bitumen is a black, highly viscous form of petroleum. Unrefined, it is unsuitable for exploitation, but it can be combined with fresh water and surfactants to create a mix which is easier to use. This bitumen mix has a density similar to water, so if it is spilled at sea, it does not float like petroleum typically does. The entire water column can be polluted.

It is not possible to clean such a spill when it has emulsified, and even tracking it can be difficult. Researchers tried laser radar in an experiment to see if they could find where the spill was headed. Within a few weeks the bitumen mix de-emulsified and re-floated. Now the authorities knew where the spill was, but trying to collect the sticky, nearly solid mass was another challenge.

Solution

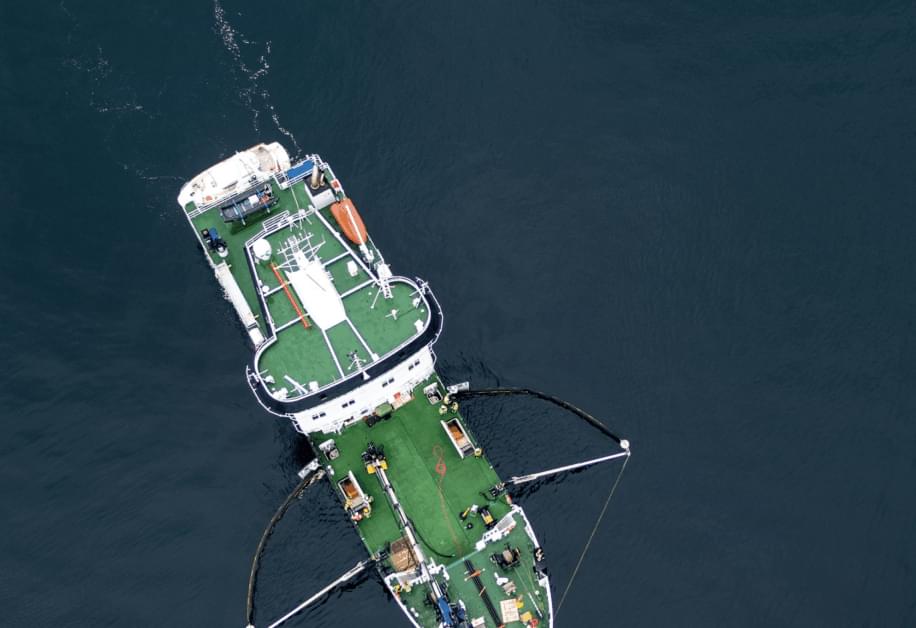

A massive clean-up operation was organised to contain and recover the spill. A defensive line protected a nearby city, tourist beaches and designated wildlife areas. Much of the bitumen was now so solid that the crew used nets to haul some of it by hand out of the water.

Oil spill recovery equipment was also deployed from Lamor, as well as others in the industry. It was a challenging task, but the ships equipped with Lamor’s in-built vessel systems not only recovered the bitumen mix, but they did it also safely and efficiently.

It is exciting that Lamor’s in-built system recovers whatever kinds of oil we have met. The team at Lamor was professional, knowledgeable, and dedicated to finding solutions to this complex problem, said Mr. Zhang Hai Feng, who oversees marine machinery on CNPC OSRV.

Lamor has a long history of oil spill recovery operations in many different conditions. Under weathering factors, oil coagulates, becoming thick, highly viscous, and nearly solid, not unlike de-emulsified bitumen. Lamor’s solutions were specially designed and manufactured to handle thick, solidified oil, but also work with other difficult materials like bitumen mix. Lamor’s equipment is made to be robust and dependable, so its unique stiff brushes technology can recover not only bitumen mix, but other thick and heavy petroleum products as well.

Impact

After two months of struggle with spilled oil, the city, tourist beaches and wildlife areas were preserved, and the bitumen mix was recovered safely and efficiently with effort from all the people and equipment involved.

It was proven that Lamor solutions effectively and efficiently work in large and complex operations involving a multitude of different equipment and operators. The end customer was impressed with the performance of Lamor’s in-built system and asked Lamor specialists to confer with them on how to deal with any similar challenges in the future.

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.