Lamor's environmental protection solutions for an American West Coast refinery

Industries face constant pressure to operate safely and efficiently while minimizing environmental impact. Oil spills are one of the most significant risks associated with industrial operations, and quick response to such incidents is critical. Lamor's innovative environmental protection solutions were used by a refinery on the West Coast of America to effectively contain an oil spill.

Challenge

American refineries work hard to prevent oil spills, but sometimes unwanted accidents happen. They must be prepared to respond quickly during an incident.

One refinery on the Pacific coast is located next to a slough which flows directly into a bay. The facility has a staff of about 500 and a capacity of over 150 thousand barrels per day. They invested in the best conventional oil spill response solutions available, including over 3,000 metres (9,000 feet) of boom, a fleet of vessels and trained teams who will respond if an accident occurs.

Accidents happen when and where we least expect them, and this is exactly what happened at the refinery. In the middle of the night during a holiday, a spill occurred into a slough at the refinery. They only had a minimal crew on hand. If the spill was not immediately contained, it would leak into the marsh and bay, killing wildlife, damaging the company’s reputation, and becoming an expensive clean-up operation.

Solution

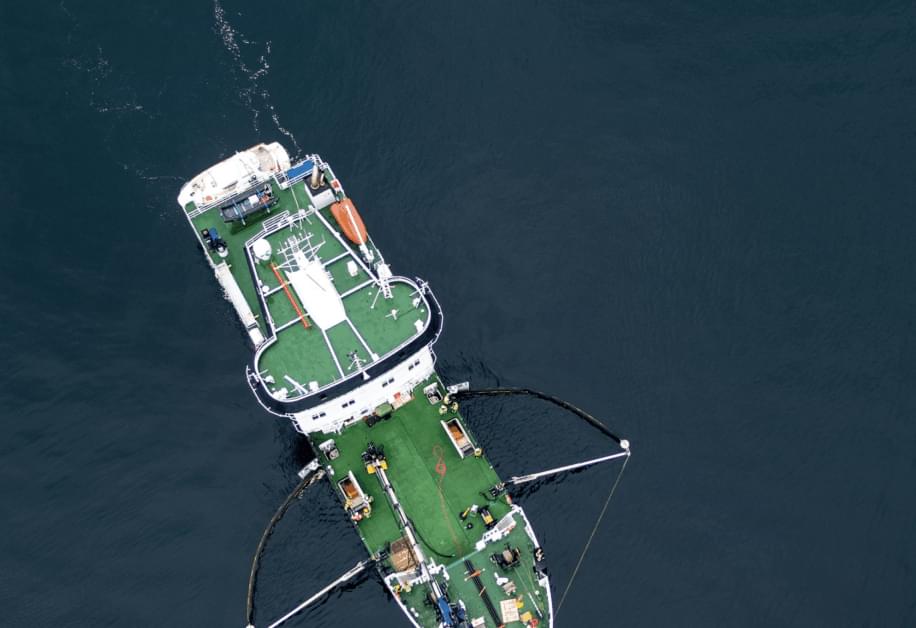

The refinery has superb conventional OSR equipment, but the team decided they needed something they could deploy quicker. They chose to use Lamor’s Harbo Boom Rapid First Response System because it is lightweight, effective, easy to use and safe to deploy. It is simple and can be used very quickly: you just open a cartridge and deploy the boom. The Harbo boom was created exactly for an incident such as this, to be on hand when a fast and efficient first response is critical. The team packed two cartridges and hurried to the site of the spill.

Within fifteen minutes, two staff members had completely contained the spill using the Harbo boom. They deployed the boom across the slough so the spill could not enter the creek and out into the bay. While the spill was contained the refinery was able to gather their onsite resources.

A huge takeaway from the field was the ease of deploying the Harbo boom with minimal staffing as the initial call was unfolding. For one person to be able to string a line across the canal and pull the Harbo boom out while a second team member held the cartridge in place was amazing, says Lamor's American customer.

Impact

The use of Lamor's solutions helped to quickly contain the spill, preventing damage to the surrounding marsh and bay, protecting wildlife, and avoiding a costly clean-up operation.

Afterwards the refinery studied the incident and concluded that the clean-up operation was a success. A key component to this was the Harbo boom because of its ease of use and rapid deployment capabilities. It has become a critical part of the refinery’s first response solutions.

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.