Bucket Skimmers

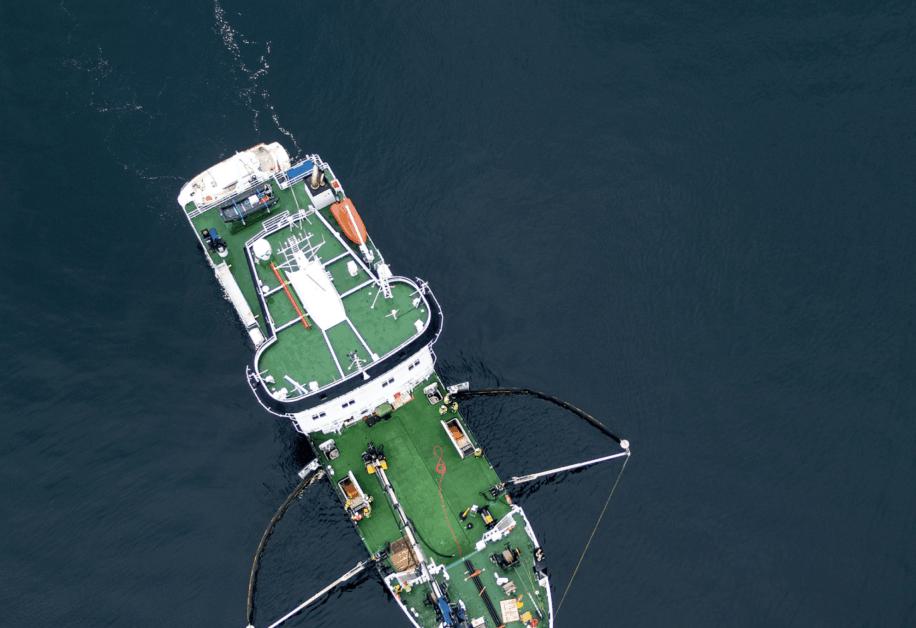

Lamor recovery bucket skimmers (LRB)

The Lamor Oil Recovery Bucket (LRB) system is ideal for pit cleaning and oil recovery operations on land, offshore and in Arctic conditions. The LRB is a light bucket skimmer that is based on the proven Lamor stiff- brush wheel technology and it automatically separates oils, emulsions and oily debris from seawater or soils.The LRB is deployed in a stationary position in skimming operations from an e.g. vessel crane, dredging machine or excavator.

“These heavy duty LRB bucket skimmers can work hard in real viscous oils in almost any situation and environmental conditions”

How it works

Bucket skimmers are deployed in a stationary position in skimming operations from an e.g. vessel crane, dredging machine or excavator. They combine the efficient oil recovery function of the brush wheel skimmer with the scraping and digging functions of an excavator scoop. The product range is winterized with heated hopper, scraper and hot water injection. Bucket skimmers are unaffected by the floating debris and free water content in recovered oil is less than 2 %. The brush wheel can be lifted with the bucket to scoop and empty heavy oil sludge and other solid materials e.g. ice particles in offshore operations. These skimmer systems can be deployed rapidly and operated by a single operator. When the system is not in use, it is stored in its own storage cradle that can be used as a washing basin for cleaning.

The Recovery Bucket should be a light Bucket Skimmer that can be effectively operated by a crane on board of a dredging barge, amphibious harvester or small on-land excavator. It should be primarily designed for pit cleaning and oil spills on land, shorelines, swamp areas or icy waters but should be usable in almost all types of spills. The complete system should also typically include a pump, oil storage facilities and all relevant hoses.

The Recovery Bucket should be based on brush technology and offer the highest possible performance and safety levels in oil spill recovery operations. The skimmer brush must be operable in both directions depending of the oil type to be collected. The Recovery Bucket system should be unaffected by the floating debris normally found in an oil slick while automatically separating oils, emulsions and oily debris from sea water or soils. Recovered oil normally contains less than 5% free water. The Recovery Bucket should be fitted with a positive displacement Archimedes screw type pump.

It should be possible to deploy and operate the Recovery Bucket by a small crew very quickly with very little specialized training required. The Recovery Bucket should have a storage container which can also be used as a washing basin for the device.

Standard Hydraulic Connectors: 3/8" TEMA 3811/3821 (Stainless steel optional extra)

Features

- Robust steel construction

- Light to heavy viscous/bitumen oils

- Header hopper for Arctic operations

- Remote controlled

- Single operator

- User friendly

Scenarios of use

- Land

- Offshore

- Arctic

- Docks, terminals & piers

- Rivers & shorelines

Related equipment

| Technical specifications | LRB 250 | LRB 150 | LRB 40 |

|---|---|---|---|

| Item ID | 365226 | 287923 | 206363 |

| Length | 2480 mm / 98 in | 1740 mm / 68,5 in | 880 mm / 35 in |

| Width | 2900 mm / 114 in | 1800 mm / 71 in | 680 mm / 27 in |

| Height | 1450 mm / 57 in | 1180 mm / 46,5 in | 800 mm / 31 in |

| Weight | 1600 kg / 3530 lbs | 650 kg / 1430 lbs | 75 kg / 165 lbs |

| Capacity | 140 m3/h / 616 gpm | 115 m3/h / 506 gpm | 19 m3/h / 83 gpm |

| Free water content | <2% / <2% | <2% / <2% | <2% / <2% |

| Hydraulic flow | 30l/min / 8 gpm | 30l/min / 8 gpm | 20l/min / 5.3 gpm |

| Hydraulic pressure | 210 bar / 3045 psi | 210 bar / 3045 psi | 180 bar / 2610 psi |

| Power | 15 kW / 20 hp | 11 kW / 15 hp | 6 kW / 8 hp |

| Suitable pump | GTA 140 | GTA 115 | GTA 20/30 |

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.