Inbuilt systems

Lamor LORS inbuilt systems

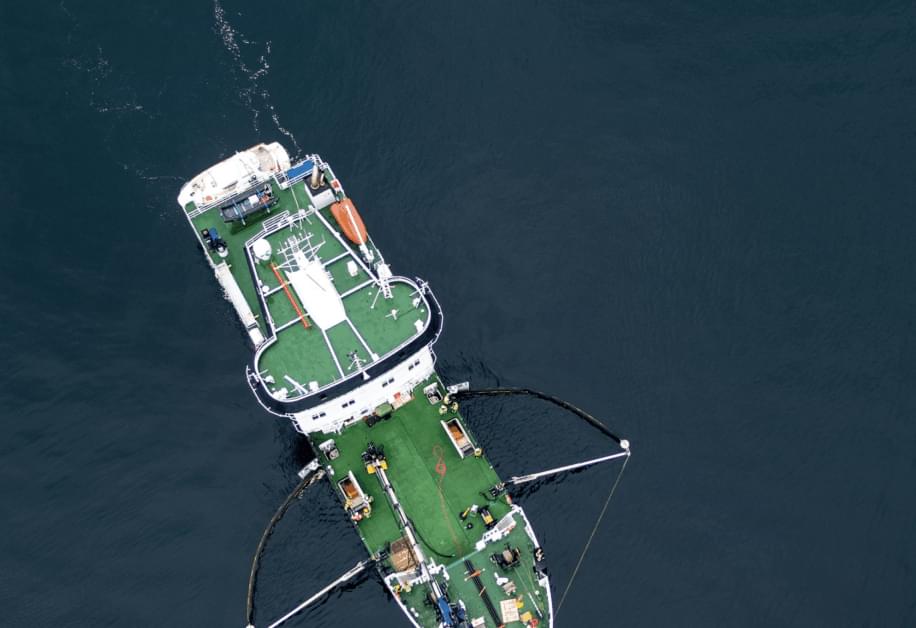

The Lamor Oil Recovery System (LORS) is a vessel mounted advancing skimming system that is based on Lamor’s proven conveyor chain brush technology. The system is designed for small workboats and tugs (7 – 15 m / 23 – 49 ft) up to medium and big vessels (15 – 85m / 49 – 278 ft) providing the highest possible performance and safety for oil spill recovery operations. Deployment of the LORS makes the entire vessel an “oil slick processing system”.

“By far, the most efficient and proven oil recovery system in the OSR market for PCVs, OSRVs, Coast Guard vessels, workboats and various size response vessels working in real oil in harsh environments at sea”

How it works

The system utilizes the vessel’s forward motion to deflect surface water and oil from the collection area that is formed by the jib arm and deflection boom into the recovery process. The flow of water carries oil through the recovery channel where the oil is efficiently separated and recovered. The recovery channel recirculates surface water back into the recovery area increasing the system’s overall throughput efficiency. The LORS operates at vessel speeds of 4 knots effectively in harsh weather and sea conditions with a high oil encounter rate with a free water content of < 5 % and does not diminish the vessel’s maneuverability

With the LORS Systems deployed, the entire vessel becomes an “oil slick processing system”. The LORS system uses the vessel´s forward motion to deflect surface water and oil from the collection area formed by the jib arm and deflection boom into the recovery channel for processing. An effective flow through the oil recovery channels is achieved by the forward speed of the ship, which induces a pressure difference between the intake and exit and is enhanced with the flow impeller in the recovery system. The skimming systems are located so that pressure fluctuations caused by boat motions and waves are minimized.

The flow of water carries oil into the recovery channel where the oil is efficiently separated by the brush pack and removed from the flow. The Brush System lifts oil, seaweed, and debris from the water which passes through the channel and returns to the collection area for further processing. The Brush Conveyor Belt

The Brush conveyor belts collects oil of all types and is unhindered by floating debris or seaweed, and lifts the recovered material to a special cleaner. This cleaner can be supplied with an optional connection for steam heat if required for extreme, cold operations. The material falls down from the cleaner to a collecting hopper, from where it is transferred to a storage tank by a powerful GTA Positive Displacement Archimedes Screw-type oil transfer pump. The pump can be fitted for hot water injections when pumping heavy viscous oil and can be used to transfer recovered oil directly to a storage tanker, depending on the operational scenario.

These proven LORS systems have been used in hundreds of real oils around the world, and by many other high-level agencies, like the Coast Guards.

Features

Able to process large areas with oil recovery speed of up to 4 knots

Quick deployment start

Little to no specialized training required to operate

Able to withstand adverse weather conditions and choppy seas

Skimming systems can be fitted in various types and sizes

Scenarios of use

- Inland

- Rivers

- Harbors, ports & terminals

- Shoreline

- Offshore

Related equipment

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.